Deskripsi

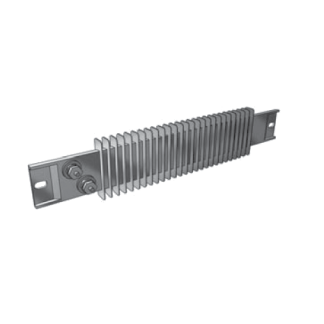

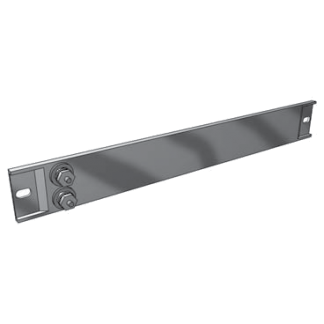

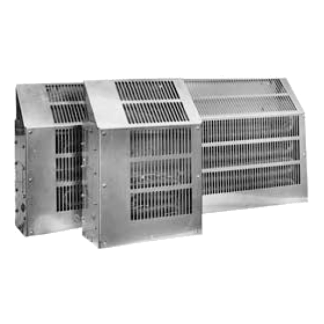

PIPE INSERT IMMERSION HEATERS

OVERVIEW

ANTUS pipe-insert immersion heaters are perfect for solutions that are difficult to heat as they require low watt density and

are mostly stored in large tanks. These heaters are primarily designed for heating viscous fluids. They are mounted in a pipe close

to the bottom of a tank. The pipe evenly transfers the heat to stored liquids.

KEY FEATURES

- Made of superior alloy-sheathed elements.

- 3” 150 lb steel flange or 2” NPT screwplug.

- Moisture-resistant terminal box.

- Single 1” NPT conduit fitting for units without a thermocouple.

- Extra 1⁄2” NPT conduit fitting for units with a built-in thermocouple.

Notes:

- Thermocouples detect rises in temperature, then automatically shut the system off.

- If the liquid level is beneath the uppermost part of the heater, the inside temperature of the heater’s pipe will increase.

- For detecting low liquid levels, use K-type thermocouple heaters with one thermocouple per tank.

- Upon request, can supply a control panel or ship the control components individually.

HEATING PROCESS

- The heating element transfers the heat to the inner wall of the pipe by convection and radiation processes. Note: Do not fill the pipe with a heat transfer fluid.

SELECTING AND SIZING YOUR ANTUS PIPE-INSERT IMMERSION HEATER

- Determine the kilowatts required to keep the tank at the required temperature.

- Select the number of heaters required with an insert length that is long enough for good heat transfer.

- Use single element or double element heaters in groups of three when installing a three-phase balanced system.

- Select the single element heater for heating a viscous liquid from a cold start, as the lower watt density you will get on the pipe surface will prevent coking