Deskripsi

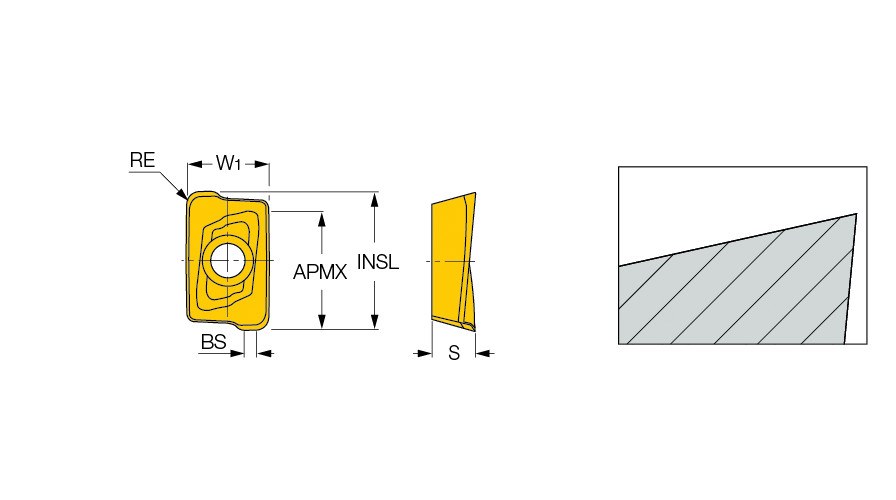

ISCAR HM90 APCT 100302R-PDR IC28 Insert

Grade : IC28

ISCAR HM90 APCT 100302R-PDR IC28 Insert. Used mainly for machning aluminum at medium cutting speeds and medium or large chip sections. The inserts usually feature very sharp cutting angles.

| ISO Range – P/M/K | |

| ISO Range – H/S/N | (N15-N30) |

| Grade or Coating Type | Uncoated |

| Coating Layers | Uncoated |

Cutting Speed for: HM90 APCT 100302R-PDR IC28 – 5602958

| ISO | Material | Material Description | Material Condition | Cutting Speed Recommendations |

|---|---|---|---|---|

| N | 21 | Aluminum-wrought alloy | Not cureable : 60 | 480-640 m/min |

| N | 22 | Aluminum-wrought alloy | Cured :100 | 400-560 m/min |

| N | 23 | Aluminum-cast, alloyed <12% Si | Not cureable : 75 | 480-640 m/min |

| N | 24 | Aluminum-cast, alloyed | Cured : 90 | 400-560 m/min |

| N | 25 | Aluminum-cast, alloyed >12% Si | High temperature :130 | 240-320 m/min |

| N | 26 | Copper alloys >1% Pb | Free cutting :110 | 240-320 m/min |

| N | 27 | Copper alloys | Brass : 90 | 240-320 m/min |

| N | 28 | Copper alloys | Electrolitic copper :100 | 160-240 m/min |

Family Designation:

HM90 APCT 1003 HELI2000 insert with a sharp cutting edge used for semi-finishing and finishing applications. Recommended for machining austenitic stainless steel, titanium and high temperature alloys.