Deskripsi

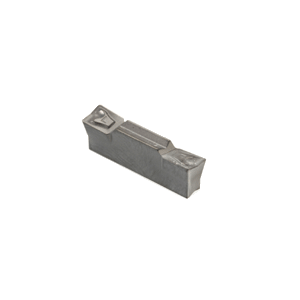

ISCAR HFPL 4004 IC20 Insert

Family Designation: HFPR/L Utility double-ended face machining inserts

Item Designation: HFPL 4004

Grade : IC20

Used for semifinishing, finishing and semiroughing of aluminum, cast iron and stainless steel. An uncoated carbide grade.

| ISO Range – P/M/K | (M10-M25)(K10-K20) |

| ISO Range – H/S/N | (H05-H15)(S05-S20)(N05-N25) |

| Grade or Coating Type | Uncoated |

| Coating Layers | Uncoated |

Cutting Speed for: HFPL 4004 IC20 – 6200041

| ISO | Material | Material Description | Material Condition | Cutting Speed Recommendations |

|---|---|---|---|---|

| P | 1 | Non-alloy steel and cast steel, free cutting steel <0.25%C | Annealed :125 | 220-290 m/min |

| P | 2 | Non-alloy steel and cast steel, free cutting steel >=0.25%C | Annealed :190 | 190-260 m/min |

| P | 3 | Non-alloy steel and cast steel, free cutting steel <0.55%C | Quench and tempered. :250 | 140-220 m/min |

| P | 4 | Non-alloy steel and cast steel, free cutting steel >=0.55%C | Annealed :220 | 160-240 m/min |

| P | 5 | Non-alloy steel and cast steel, free cutting steel >=0.55%C | Quenched & tempered. :300 | 130-210 m/min |

| P | 6 | Low alloy & cast steel (less than 5% of alloying elements) | Annealed :200 | 160-240 m/min |

| P | 7 | Low alloy & cast steel (less than 5% of alloying elements) | Quenched & tempered :275 | 130-220 m/min |

| P | 8 | Low alloy & cast steel (less than 5% of alloying elements) | Quenched & tempered :300 | 130-210 m/min |

| P | 9 | Low alloy & cast steel (less than 5% of alloying elements) | Quenched & tempered :350 | 110-190 m/min |

| P | 10 | High alloyed steel, cast steel and tool steel | Annealed :200 | 190-260 m/min |

| P | 11 | High alloyed steel, cast steel and tool steel | Quenched & tempered :325 | 110-190 m/min |

| P | 12 | Stainless steel and cast steel | Ferritic/martensitic :200 | 120-250 m/min |

| P | 13 | Stainless steel and cast steel | Martensitic :240 | 110-230 m/min |

| M | 14 | Stainless steel and cast steel | Austenitic :180 | 100-220 m/min |

| K | 15 | Grey cast iron (GG) | Pearlitic/ferritic :180 | 60-104 m/min |

| K | 16 | Grey cast iron (GG) | Pearlitic/martensiti :260 | 47-77 m/min |

| K | 17 | Nodular cast iron (GGG) | Ferritic :160 | 57-97 m/min |

| K | 18 | Nodular cast iron (GGG) | Pearlitic :250 | 44-77 m/min |

| K | 19 | Malleable cast iron | Ferritic :130 | 64-97 m/min |

| K | 20 | Malleable cast iron | Pearlitic :230 | 54-87 m/min |

| N | 21 | Aluminum-wrought alloy | Not cureable : 60 | 334-967 m/min |

| N | 22 | Aluminum-wrought alloy | Cured :100 | 252-670 m/min |

| N | 23 | Aluminum-cast, alloyed <12% Si | Not cureable : 75 | 269-844 m/min |

| N | 24 | Aluminum-cast, alloyed | Cured : 90 | 184-517 m/min |

| N | 25 | Aluminum-cast, alloyed >12% Si | High temperature :130 | 174-317 m/min |

| N | 26 | Copper alloys >1% Pb | Free cutting :110 | 167-317 m/min |

| N | 27 | Copper alloys | Brass : 90 | 129-242 m/min |

| N | 28 | Copper alloys | Electrolitic copper :100 | 89-167 m/min |

| N | 29 | Non metallic | Duro& fiber plastics : 60 | 50-200 m/min |

| S | 31 | High temp. alloys Fe based | Annealed :200 | 25-35 m/min |

| S | 32 | High temp. alloys Fe based | Cured :280 | 19-34 m/min |

| S | 33 | High temp. alloys. Ni or Co based | Annealed :250 | 19-27 m/min |

| S | 34 | High temp. alloys. Ni or Co based | Cured :350 | 15-20 m/min |

| S | 35 | High temp. alloys. Ni or Co based | Castr :320 | 15-20 m/min |

| S | 36 | Titanium (pure) | Pure :310 | 77-107 m/min |

| S | 37 | Titanium Ti alloys | Alpha+beta alloys cu :310 | 20-47 m/min |

| H | 38 | Hardened steel | Hardened :560 | 20-35 m/min |

| H | 39 | Hardened steel | Hardened :654 | 18-28 m/min |

| H | 40 | Chilled cast iron | Cast :400 | 25-45 m/min |

| H | 41 | Cast iron | Hardened :560 | 23-35 m/min |