Deskripsi

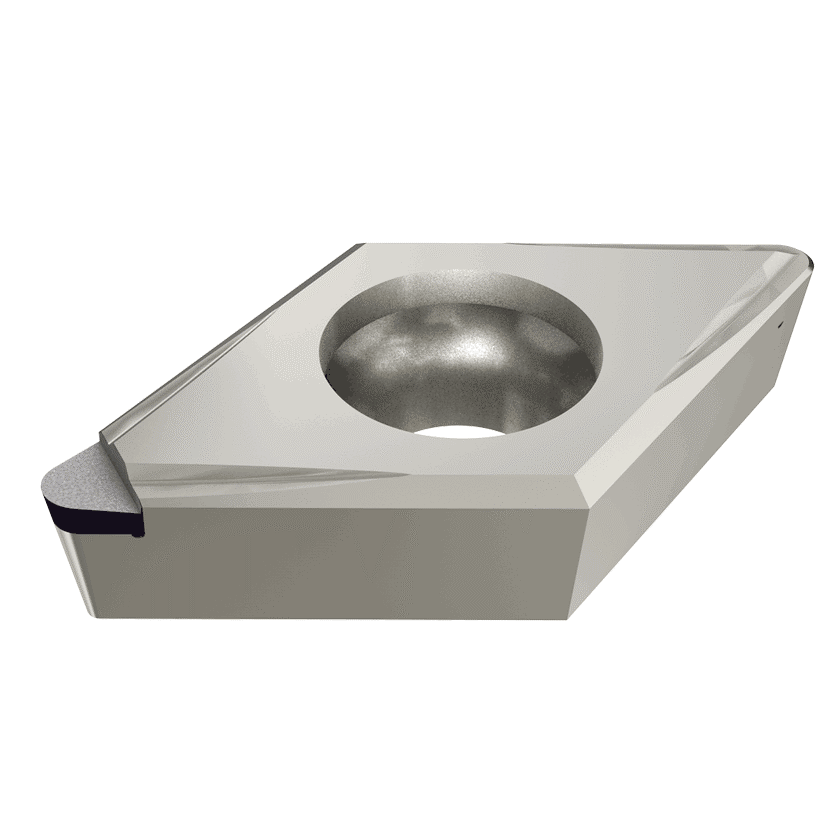

ISCAR DCMT 11T308D ID5 Insert

Family Designation: DCMT (PCD) 55° rhombic inserts with PCD single top corner brazed tip and positive rake angle, used for finishing aluminum

Item Designation: DCMT 11T308D

Grade : ID5

A PCD brazed tip, suitable for machining aluminum (Si < 12%) and copper alloys and general cutting o f non-ferrous materials.

| ISO Range – P/M/K | |

| ISO Range – H/S/N | (N01-N10) |

| Grade or Coating Type | PCD |

| Coating Layers | Uncoated |

Cutting Speed for: DCMT 11T308D ID5 – 5700455

| ISO | Material | Material Description | Material Condition | Cutting Speed Recommendations |

|---|---|---|---|---|

| N | 21 | Aluminum-wrought alloy | Not cureable : 60 | 600-2500 m/min |

| N | 22 | Aluminum-wrought alloy | Cured :100 | 600-2500 m/min |

| N | 23 | Aluminum-cast, alloyed <12% Si | Not cureable : 75 | 600-2500 m/min |

| N | 24 | Aluminum-cast, alloyed | Cured : 90 | 600-2500 m/min |

| N | 25 | Aluminum-cast, alloyed >12% Si | High temperature :130 | 500-1200 m/min |

| N | 26 | Copper alloys >1% Pb | Free cutting :110 | 600-1000 m/min |

| N | 27 | Copper alloys | Brass : 90 | 600-800 m/min |

| N | 28 | Copper alloys | Electrolitic copper :100 | 600-800 m/min |

| N | 29 | Non metallic | Duro& fiber plastics : 60 | 800-2000 m/min |

| N | 30 | Non metallic | Hard rubber : 55 | 600-1200 m/min |